What is Appliance Testing?

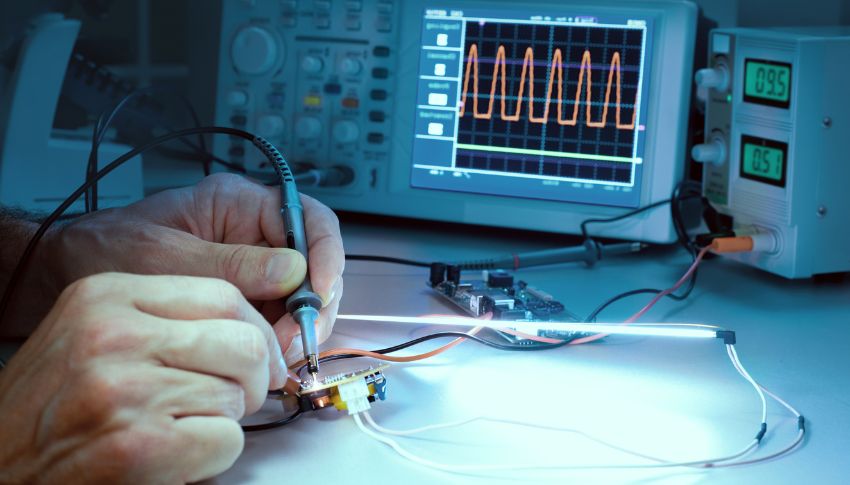

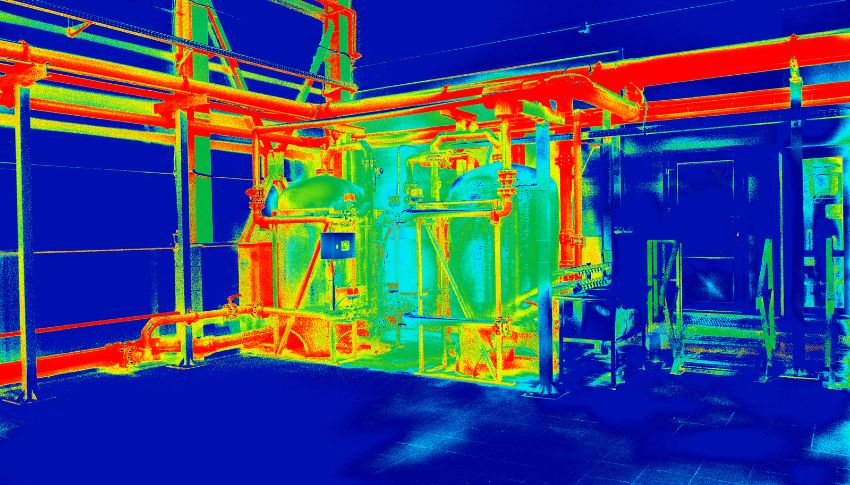

Appliance Testing, commonly known as Test and Tag, is a crucial process that involves the inspection and testing of electrical appliances to ensure their safety and compliance with regulatory standards. This procedure typically includes both a visual inspection for signs of wear or damage and electrical testing to verify that the appliance is electrically sound.

Who Needs Their Equipment Test and Tagged?

Test and Tag is essential for a wide range of businesses and organizations, including:

- Workplaces - Offices, factories, warehouses, and other work environments.

- Events - Concerts, conferences, trade shows, and public gatherings.

- Construction Sites - Tools and equipment used in construction projects.

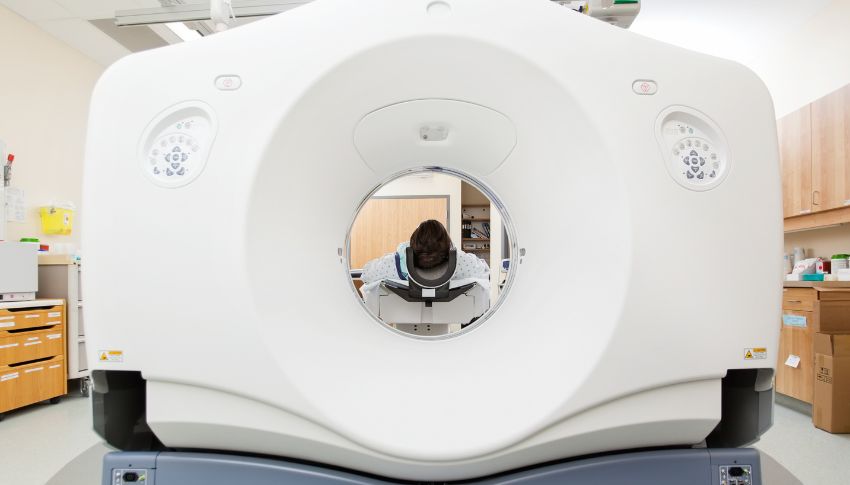

- Hospitals and Healthcare Facilities - Medical equipment and devices.

- Schools and Educational Institutions - Appliances used in classrooms and labs.

- Rental Properties - Landlords ensuring the safety of electrical appliances for tenants.

What Can We Do for You?

We offer comprehensive Appliance Testing services to address your safety and compliance needs:

- Thorough Inspections

- Electrical Testing

- Test and Tag Certification

- Customized Testing Schedules

- Compliance Assistance

- Risk Mitigation